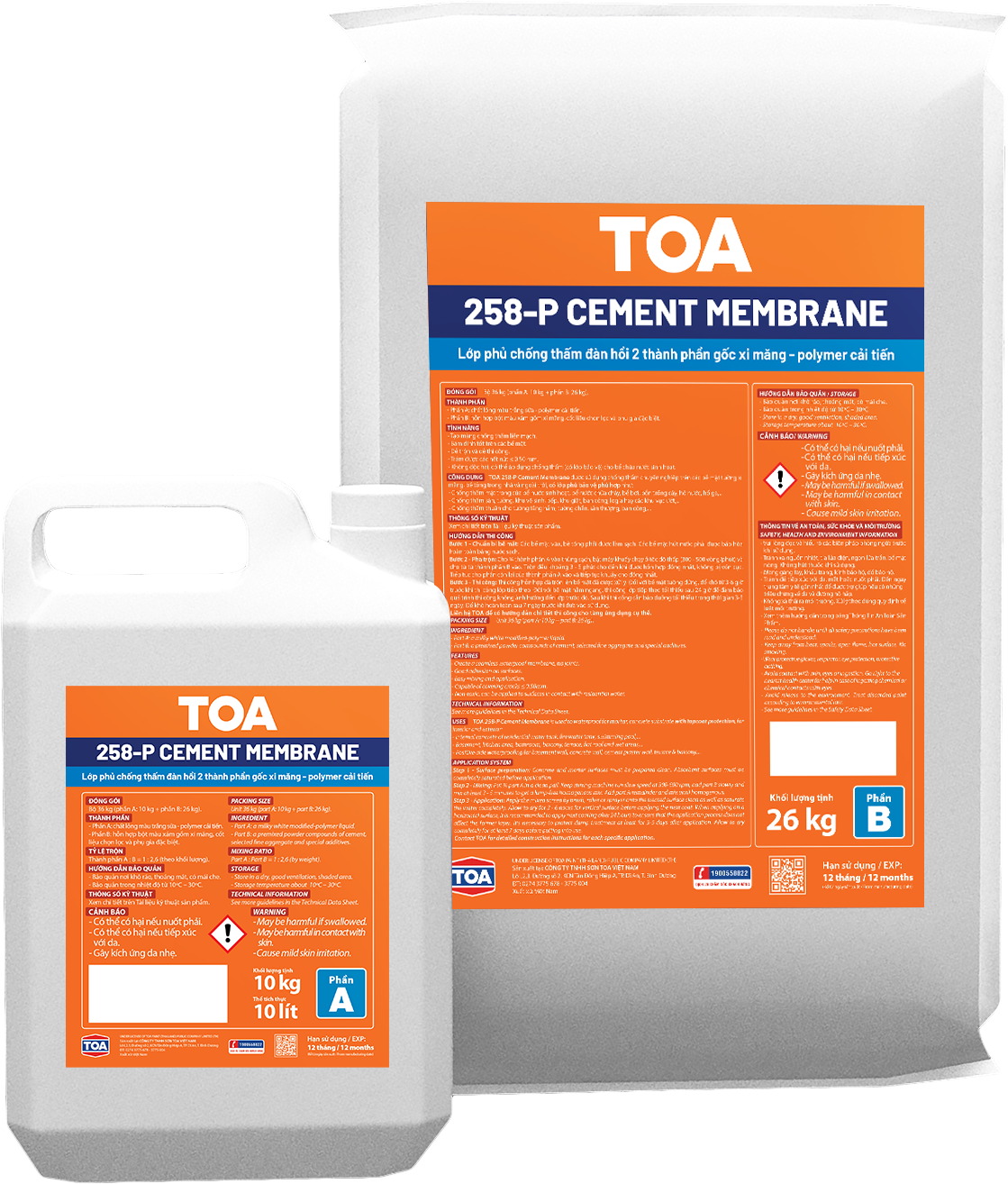

TOA 258-P Cement Membrane

TOA 258-P Cement Membrane is a two pack cement waterproofing cement based. Part A is modified polymer liquid and part B is a pre-mixed powder compounds of cement, selected fine aggregate and special additives. These two components, when mixed together, form a liquid mortar solution that is convenient for application on mortar and concrete surfaces to form a high elastic coating with waterproof and protective properties.

TOA 258-P Cement Membrane has the following outstanding features and benefits:

1. Packed in convenient mixing ratio for easy mixing and application.

2. Improved polymer composition increases good adhesion on surfaces.

3. Create a seamless waterproof membrane, no joints.

4. Capable of covering cracks ≤ 0.50mm.

5. The product is non-toxic and suitable for application on surfaces in contact with domestic water – compliant with the national technical regulation QCVN 01-1:2018/ BYT on the quality of clean water used for domestic purposes.

View DetailCompact

Intended use:

TOA 258-P Cement Membrane used professionally for waterproofing on cement wall surfaces, concrete, mortar, brick, indoor and outdoor and used for new construction and renovation works such as:

1. Waterproofing the inside of residential water tanks, fire water tanks, swimming pools, planting tanks, water holes, manholes, etc. before plastering or finishing tiles.

2. Waterproofing floors, walls of toilets, kitchens, laundry areas, balconies, loggias or wet areas, etc. before finishing tiles and stones.

3. Waterproofing for basement walls, retaining walls, balcony terraces, etc. with protective plaster.

.png?v1.0)